Makers 1-on-1 is our original interview series featuring today's makers and DIYers. We're sitting down with new makers every week to learn more about their projects, how they acquire information, their purchase processes, and their passions.

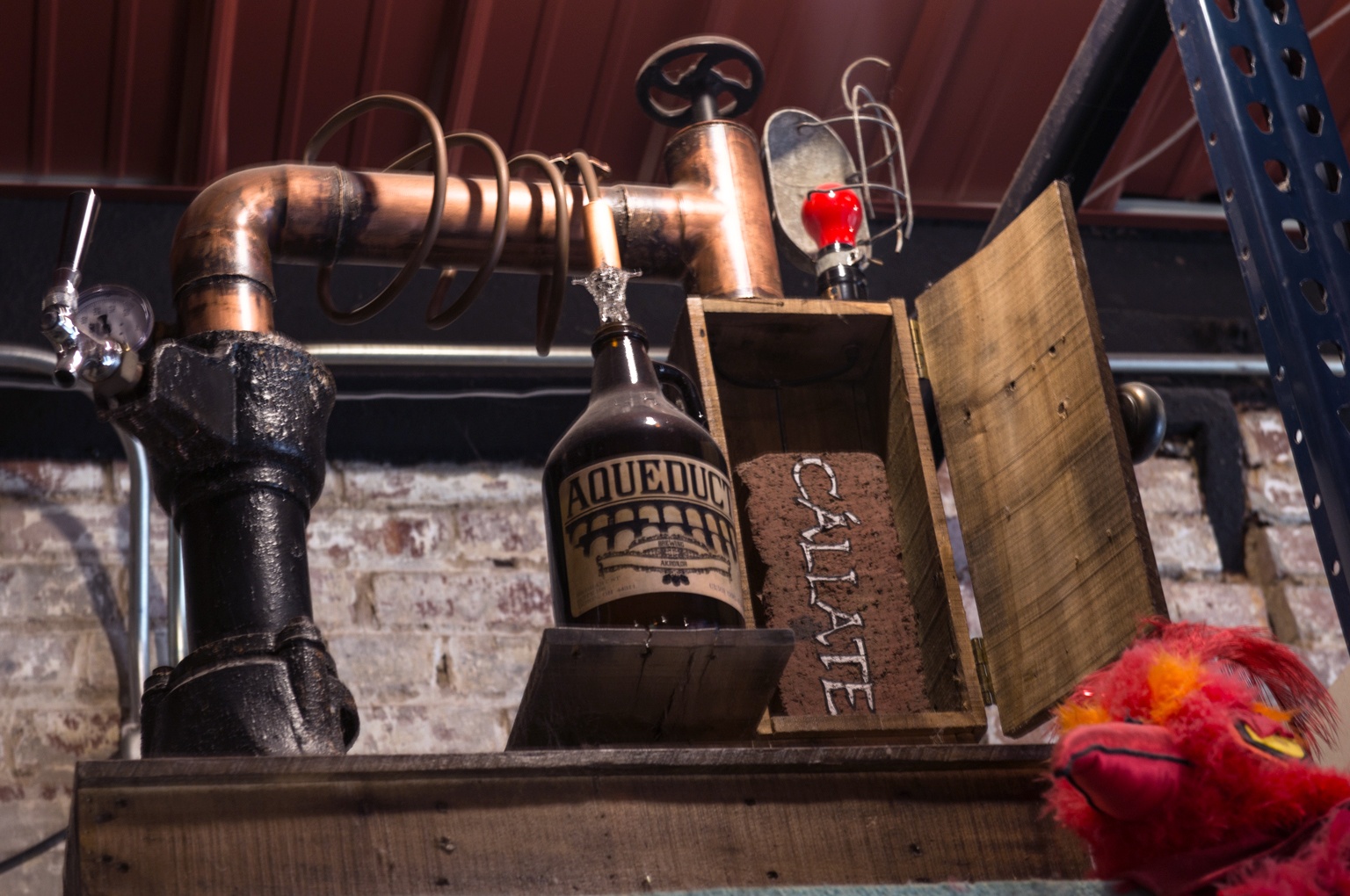

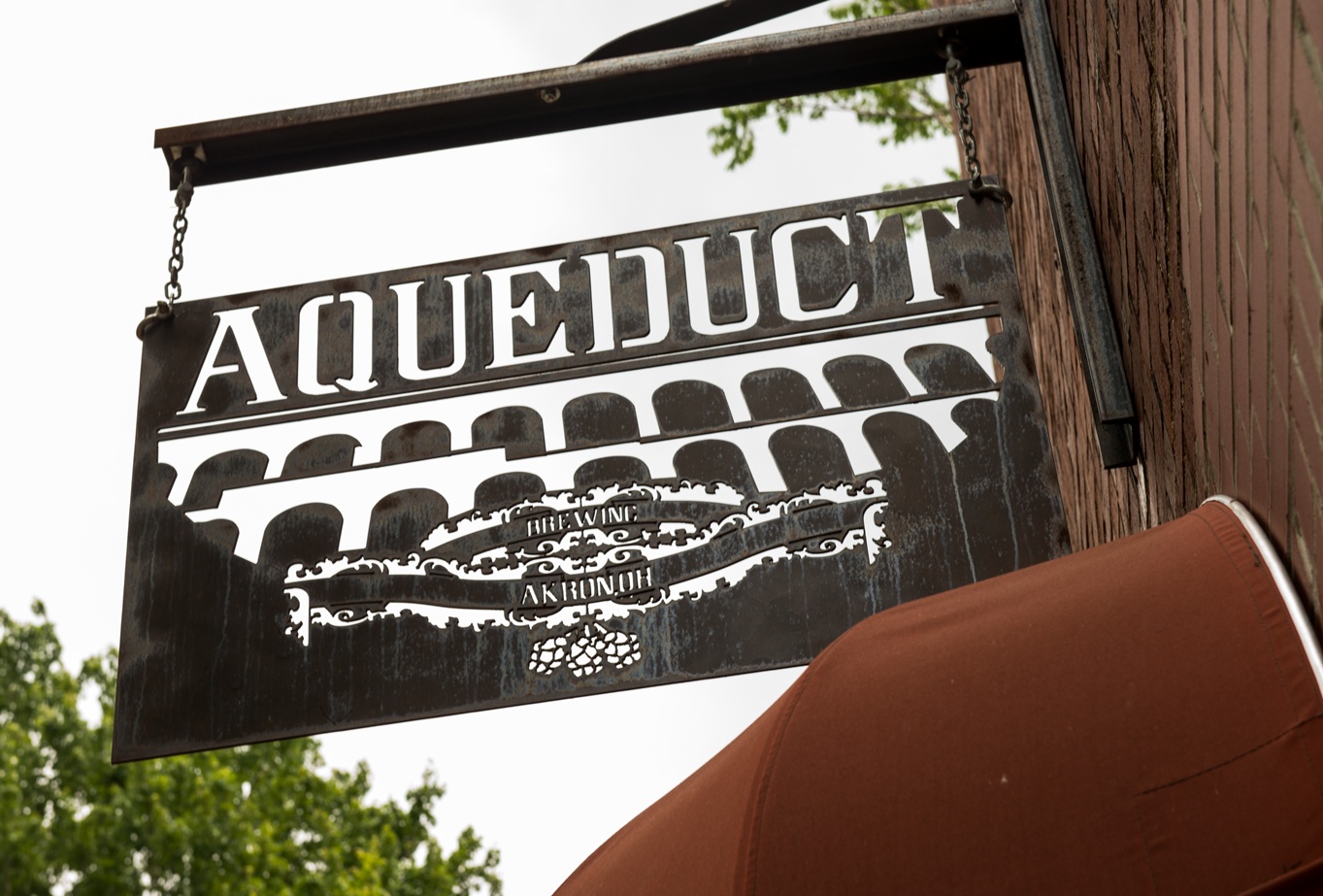

This week, we’re interviewing Robert and Sara Hernandez, founders of Aqueduct Brewing in Akron, OH. This husband and wife team opened their own bar and patio where they brew their craft beers from scratch. At Aqueduct, they need ingredients like grains, hops, and other unique flavors, as well as equipment like hot liquor tanks, mash tuns, and boil kettles. If your brand sells to craft brewers or food artisans, this 1-on-1 interview with Robert and Sara will give you some important insights to help you build connections with makers like them.

This week, we’re interviewing Robert and Sara Hernandez, founders of Aqueduct Brewing in Akron, OH. This husband and wife team opened their own bar and patio where they brew their craft beers from scratch. At Aqueduct, they need ingredients like grains, hops, and other unique flavors, as well as equipment like hot liquor tanks, mash tuns, and boil kettles. If your brand sells to craft brewers or food artisans, this 1-on-1 interview with Robert and Sara will give you some important insights to help you build connections with makers like them.

What are your names and what do you do?

Robert (R): I’m Robert Hernandez, and I am the brewer, operator, bartender, floor sweeper, toilet cleaner, everything-er of Aqueduct Brewing.

Sara (S): I’m Sara Hernandez, and I am the owner, operator, sweeper, recipe idea person, and social media manager.

How and when did you start brewing beer?

R: I used to brew with another gentlemen for a number of years. One day we just said, “Why don’t we give it a shot? Why don’t we open up a little brewery?” That was probably about six years ago now. When we actually founded the LLC Aqueduct Brewing, he ended up backing away from it because according to him, it was gonna be too much work, too hard. So Sara and I sat down and looked at our finances and jumped in. You gotta be a little crazy to start a brewery! Or a lot of crazy!

What kind of steps are involved in the day to day or running a brewery?

R: It depends on the day. We have brew days and non-brew days. On non-brew days, we generally transfer beer, keg beer, carbonate beer. It’s all about cleaning and transferring and the movement of beer. On brew days, generally on the day prior, we’ll mill all of the grains, get the water ready, and then at 8 in the morning, we start the fire. We do direct fire brew. Then, on average, that takes six to eight hours depending on the batch size.

What are some common materials you use on a daily basis when you are brewing beer?

R: Malt, malted grains. So it’s a barley, and depending on what kind of beer it is, it’s roasted differently — how much or how little. And then we use palletized hops for the most part. That way you can control the bitterness as opposed to fresh hops, which would have a very short shelf life. Today, for instance, we made a honey whit. So we added honey, orange, and coriander into the boil as well. Materials depend on the beer, but pretty much every beer has barley and hops.

What equipment do you need for brewing?

R: We have a milling table which mills all of the grains. We get them uncrushed, then we crush them ourselves. Then we have three different pots, which are the hot liquor tanks, the mash tun, and the boil kettle. Then, of course, there are pumps and valves and transferring. The mash tun is where the sugar is extracted from the starch. So actually, the starch is what is in the grain, and at a specific temperature, starch converts to sugar. Then you boil that to get out all of the impurities but also bring out the flavor of the hops. After that, we put it in a fermenter, a stainless steel tank, and then it ferments for anywhere from three to 14 days. Some of the beers, like the honey whit, will take a little longer because there is a lot more sugar to ferment out.

How do you choose which materials you're going to put into a brew?

R: So we start off with small batch — a 5 gallon batch. We’ll test that out and see what it tastes like. If it’s something we want to move forward with then we’ll scale it up slowly. If there are off flavors or it doesn’t taste good, or we would like to see something different, bold or less bold, whatever it is, then we’ll redo the batch again. We have done that a few times with the 5 gallon before we opened. I spent that entire summer just making 5 gallon after 5 gallon batch. My friends were really happy because I gave away a lot of beer.

S: Basically, you come up with a style of beer you wanna do or flavors you wanna do. And then you figure how to make that flavor, and you pick the ingredients you think will combine well and come up with that flavor that you wanted.

Where do you get more information about brewing or creating new styles?

R: Initially there was a lot of research involved. There was reading books. I still read things like The Brewers Bible and trade magazines. As the years have progressed, you start to learn what kind of hops does what, what grain does what, how long a boil, how long a fermentation, types of yeast, all different components of the beer. Research is still involved in making a new batch, but not as much.

S: Some of it is just trial and error, like how we learned when best to add certain flavors. So there are some things you wanna add during the boil, and there are some things you wanna add right before you keg. So if you want a big bold flavor of like our Fluffer-Nutter, we put vanilla and peanut butter in right before we keg it because that gives it that big, bold flavor.

What is your purchasing process for materials?

R: Most of the stuff we get for the brewing process comes from LD Carlson. It’s one of the largest distributers for beer- and wine-making products on the eastern coast. We are lucky enough to have them located right here in Kent — a local business owned by a local family. We put the order in on their website and we go in and pick it up.

What social media platforms are you active on and how do yo use them?

S: Facebook, Instagram, Twitter, and we have our own website. So the Facebook page has all of our information. We try to keep that updated with our events as much as possible. The Instagram and Twitter again are just ways to advertise the things we are doing. Customers use it to follow us, to post things they are doing, to take pictures of the beer they’re drinking, or when we have the open-mic nights, they post things to our page. I try to keep our actual website updated as much as possible with our most accurate list of the beer.

Where do you get inspiration for the new flavors you create?

S: “I wonder what this would taste like?” There has been a number of those. So when we started out, Robert started with your basic, “I wanna have an amber, I wanna have an IPA, I wanna have a whit.” The basic styles that most people know at least something about. When we first started we had maybe five to seven styles that we had on almost all the time. And then from there we had to figure out, “What do we want to add, what do we want to subtract, what do we want to try?” Also, customers would say, “Hey, ya know I had this at this place. Do you do that style?” We used to have a plain-flavored pilsner, but then we made one with raspberry. With the honey-whit we wanted to add a fruit to it, but we don’t want to do raspberry because everyone does raspberry. I said, “Well, I want to do blueberry!” So we did blueberry.

What is the most rewarding part about what you do?

S: For me, I would say it’s the friendships we’ve made. We have a lot of people that started off as customers and became regulars and are now friends, and will probably be friends for a long time to come. We have one guy who comes every week, several times a week. He works in the area so he comes all the time. We’ve got friends now that we hang out with outside of work, our kids are even friends. So for me, the best part has been getting to sit and talk to people and meet people.

R: I echo that. Except, or, along with that, I would also say watching the industry change. We’ve been open for two and a half years now, now there’s so many other breweries in town. They’re popping up everywhere. The climate has changed. It is less about going to the club, drinking a Budweiser, drinking a Miller Coors, to let’s go experiment with this. People are more accepting, more willing to try something different. Not everybody, but most will try something different. It is a great industry to just watch grow.

How else have you noticed the industry changing?

S: So we started as a husband and wife team. Since then, a lot of breweries that have opened are the same, husband and wife teams or multiple husband and wife teams. So more and more women are getting into this, which is a great thing. Women like beer too! We purposely list me as the owner for that reason. So I am trying to kind of bring that out. I have gotten in contact with a lot of the female owners of breweries in this area. We’re gonna get together, and we’re going to start having meetings. We’re resources for each other, and we get the fact that women are brewers too out there. There is an intimidation factor for some women. I’ve heard that echoed with some of the other owners. We’re trying to dispel the sexism in the industry. I am not going to be able to solve the problem myself, but I would like to make a dent in it.

How do you connect with other brewers? Do you find support in the community?

S: The craft beer community as a whole is a welcoming community. We don’t see each other as competition. The more of us there are, the better we all do. Robert can walk over to another brewery any time he wants with a question, and they are always happy to answer. A couple times, there were batches we probably would have thrown out if they hadn’t said “Hey, wait a minute, that’s good, don’t throw it out.” We started trying to help the artistic community as much as possible when we first started, too. We have a loyal following of local musicians, artists, those types of people that are trying to help us succeed. They come in and do our open-mic nights. We have events here so a lot of them are very supportive of us.

What motivates you to keep brewing? Is it a challenge or something you do to relax and enjoy?

S: Maybe when you first started brewing it was something fun to do.

R: It is challenging, but not in the traditional “I have to overcome that hill” way. It’s challenging because it’s a business. That’s a challenge, to make a business last and to be successful. Most businesses fail within the first year. We are lucky enough that we’ve surpassed two and a half years being open, three years being in the space. We are growing. We are getting ready to even do our our next small expansion, hopefully by the end of this summer. So it’s really just a rewarding ideal to find something you are passionate about because it was a hobby that turned into a passion, and a passion that has turned into a profession.

S: The fact that he is able to be happy with the job he has and is not sad he left his previous employment, that says he likes his job. There are a lot of people in this world that can’t say that. So the fact that he can is a pretty rewarding thing right there.

How do you deal with problems and challenges that you face?

R: Head on! Figure it out. Fix it if it’s broken, break it if it’s not. Everything has a solution. I have never come across anything that’s made by man that can’t be taken apart, fixed, and put back together. So as a business owner, and as a brewer, you have issues that come up. And you have to find the solution to it, and there’s no manual, there’s no book. There’s usually not a website that is going to say, “This is how you fix this.” So you just have to figure it out. You have to have some mechanical inclination. You have to have some thinking-outside-of-the-box ability. And then you have to have a fix-it mentality. I’m gonna figure it out. I am going to figure it out or it is going to kill me.

S: We have to have that “don’t quit” mentality, or else we wouldn’t be here. There are so many things that have happened. Just day one, when they started moving equipment out of this room, I mean from day one things have happened, like the forklift fell through the floor! If we had had a “Well, now what?” mentality, we wouldn’t be where we are.